Reliability Terminology

1.What is Reliability

Reliability refers to the ability of the product to complete the specified function under the specified conditions and within the specified time;

All reliability items simulate the process of storage or use under different conditions after the product is manufactured.

2.Why to do Reliability

New product assessment: To prove that the currently designed of product has the ability to meet the specified service life;

Mass production monitoring: The process will not be very smooth all time in mass production, reliability monitoring can detect anomalies during mass production in time to ensure product quality.

Expected Life

Consumer:≤5 years

Industrial:5~10 years

Automotive:>15 years

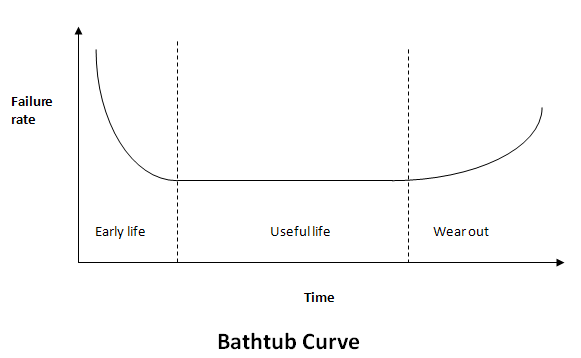

3.The Bathtub Curve for Failure Rate

Early Life

The early life failures are process related, especially for Memory/Logic device, it’s a decreasing failure trend.

Useful Life

The useful life failures are random and low failures rate, it’s a constant failure trend. Most device worked on this area.

Wear-out

The wear-out failures are inherent of process. These failures would be due to oxide wear-out, Electron migration etc. It’s an increasing failure rate.