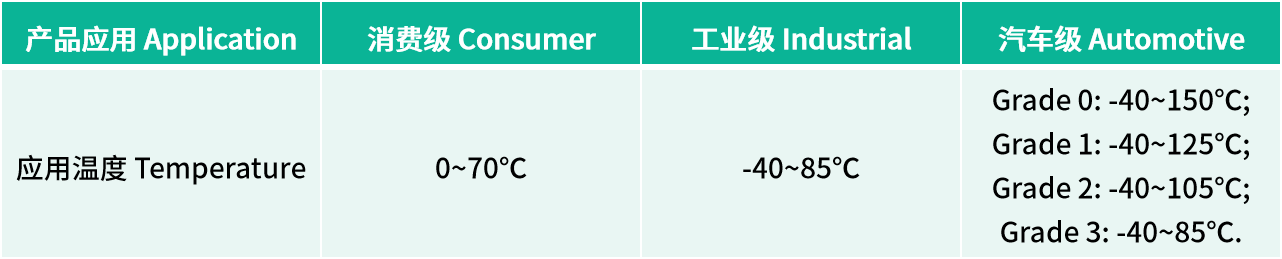

Reliability Testing

1. Application Temperature

2.Description

Reliability test is the acceleration test, and the stress items are designed on the basis of various theoretical models and statistics.

Different stress have the ability to detect different failure modes and the failure rate, and some experiments can also predict the service life of the product, usually using failure in time (FIT) as the calculation unit to indicate the product life, 1FIT represents 1 billion components within 1 hour, there may be a failure.

3. Reliability Item

High Temperature Operational Life (HTOL)

Purpose: This Determine the effects of bias conditions and temperature, simulate the actual working environment of the product. It can evaluate life time of device.

Common condition: Tj>= 125ºC, Vcc max

ESD– Human Body Model (HBM)

Purpose: To test and classify microcircuits according to their susceptibility to damage or degradation by exposure to a defined electrostatic Human Body Model discharge.

Common condition: testing on every pin.

ESD-Charged Device Model (CDM)

Purpose: To test and classify microcircuits according to their susceptibility to damage or degradation by exposure to a defined electrostatic Charged Device Model discharge. CDM Simulate a charged device to release the charges.

Common condition: The recommended voltage levels for CDM ESD testing are: 250V/500V/1000V/2000V, ESD-CDM can also happen on ATE.

High Temperature Storage Life (HTSL)

Purpose: To determine the effects of time and temperature, under storage conditions, for thermally activated failure mechanisms and time-to failure distributions of solid state electronic devices.

Common condition: 150℃, 1000hrs.

Precondition (PC)

Purpose: Establishes an industry standard preconditioning flow for non-hermetic solid state SMDs (surface mount devices) that is representative of a typical industry multiple solder reflow operation. Simulate the process from Sub-con to customer welding.

Common condition: Bake (Bake 24 hours @125ºC, remove moisture) + Moisture sock (MSL1/2/3…) + Reflow (bare reflow)

PC - Moisture Sensitivity Level (MSL) define rule

Customer or market demand;

Generally level that achieved in the industry;

Capacity of assembly house for mass production;

Capacity of BOM or BOM/process optimization;

Generally, MSL of the 2nd source should follow the 1st source;

Generally, MSL1 is the first choice for WB small package size;

Except the special case, the same package will keep the same MSL in one assembly house.

Temperature Cycle Test (TCT)

Purpose: To determine the ability of components and solder interconnects to withstand mechanical stresses induced by alternating high and low temperature extremes. Permanent changes in electrical and/or physical characteristics can result from these mechanical stresses.

Common condition: -65~150℃, at lease 500cycles

Pressure Cooker Test/Autoclave (PCT/AC)

Purpose: To evaluate the moisture resistance integrity of non-hermetic packaged IC using moisture condensing or moisture saturated steam environments. It is a highly accelerated test which employs conditions of pressure, humidity and temperature under condensing conditions to accelerate moisture penetration through the external protective material or along the interface between the external protective material and the metallic conductors passing through it.

Common condition: AC: 121℃, 100%RH, 29.7Psia; UHAST: 130℃, 85%RH, 33.3Psia.

Highly Accelerated Temperature and Humidity Stress Test (HAST)

Purpose: To employ severe conditions of temperature, humidity, and bias which accelerate the penetration of moisture through the external protective material or along the interface between the external protective material and the metallic conductors which pass through it.

Common condition: 130℃/85%RH, Vcc max